|

Wuxi Techwell Machinery Co., Ltd

|

Standard Wide Span IBR Roofing Sheet Roll Forming Machine With 5.5 Kw Main Motor Power

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

IBR Roofing Sheet Roll Forming Machine

Drive Type: Chain Drive

Forming Speed: 0-15m/min

Main Power: 5.5Kw

Standard Wide Span IBR Roofing Sheet Roll Forming Machine With 5.5 Kw Main Motor Power

Maintenance of IBR Roofing Sheet Roll Forming Machine

Daily maintenance plays an very importance role in extending the operation time and of IBR roofing sheet roll forming machine and the good quality finished IBR roof panel. The following points should be part of the machine's daily production and usage routine.

Regularly lubricated the outside parts of the IBR roof sheeting roll forming machine, such as the driving chain...

Regularly brush the surface of roller, particularly when working outside. If you do not use the IBR roof sheeting roll forming machine in a long time, you should apply luricating oil on the roller surface, make sure you clean it for next time running machine.

If the IBR sheeting roll forming machine is not operated in a long period, should cover it with plastic film, to avoid getting rain or dust on the machine, or avoid the machine becoming dampt, especially the PLC electric control board.

Make sure the cutting system of IBR sheet roll forming machine is lubricated when necessary.

Check the Hydraulic station often and the oil quantity of the deceleration machines, add more oil if the oil level is low.

Check the electric appliances box and every leads conjuction circumstance of the ibr roof sheet roll forming machine.

Specifications of IBR Roofing Sheet Roll Forming Machine

| Coil Material | Thickness | 0.3-0.8mm |

| Coil width | Custom-made, 925mm or 940mm | |

| Yield Strength | 250-350 Mpa | |

| Material | PPGI, Color Steel, GI. | |

| Decoiler / Uncoiler | Decoiler Type | Manual or Hydraulic or Auto Type |

| Coil Width | Max. 1250mm | |

| I.D | 508-610mm | |

| O.D | Max. 1500mm | |

| IBR Roofing Sheet Roll FormingMachine | Forming Stations | 16-18 Stations ( Depend on Profiles ) |

| Roller material | 45# steel, surface coated with 0.05mm hard chrome | |

| Diameter of shaft | 76mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Chain transmission | |

| Forming speed | 0-15m/min | |

| Main power | 5.5KW | |

| Cutting Device | Cutting type | Hydraulic cutting |

| Cutting Die Material | Cr12Mov steel, HRC58-62 | |

| Cutting power | 3KW | |

| CuttingTolerance | 10m+/-1.5mm | |

| Encoder | OMRON Brand | |

| Electrical Control Box | PLC | PANASONIC Brand |

| Inverter | YASKAWA Brand | |

| Touch screen | PANASONICE | |

| Operation type | Touch screen & Button | |

| Hydraulic Station | Hydraulic station | Famous Chinese brand |

| Support Table | Table type | Simple nonpower type |

| Function | To support the finished panels |

Main Components of IBR Roofing Sheet Roll Forming Machine

| Decoiler / Uncoiler | 1 Unit |

| Feeding Guide | 1 Unit |

| IBR Roofing Sheet Roll Forming Machine | 1 Unit |

| Hydraulic Cutting Part | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Support Table | 2 Units |

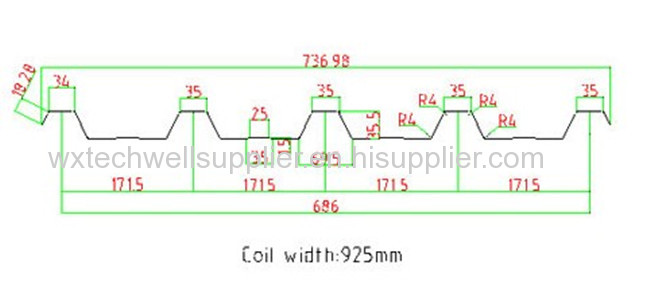

Reference IBR Sheet Profile Drawing

Applications

IBR Roofing Sheet, IBR Sheeting, IBR Roof Panel, IBR Panel, Trapezoidal roof panel, trapezoidal sheet, trapezoidal roof metal, trapezoidal roofing, metal roof; steel roof; metal roof wall panel; steel roof wall panel; metal roofing sheet; steel roofing sheet; metal roof panel; steel roof panel; roof wall cladding; roof cladding; wall cladding

Our Advantages

Copra designing software

5-8 technicians every month specially do international installation and debugging

High Quality

Reasonable Price

Good after Service

1 Year Warranty

More Than 10 Years Experience