|

Wuxi Techwell Machinery Co., Ltd

|

Auto Size Changing Cable Tray Profile Making Machine / Cable Tray Manufacturing Machine

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

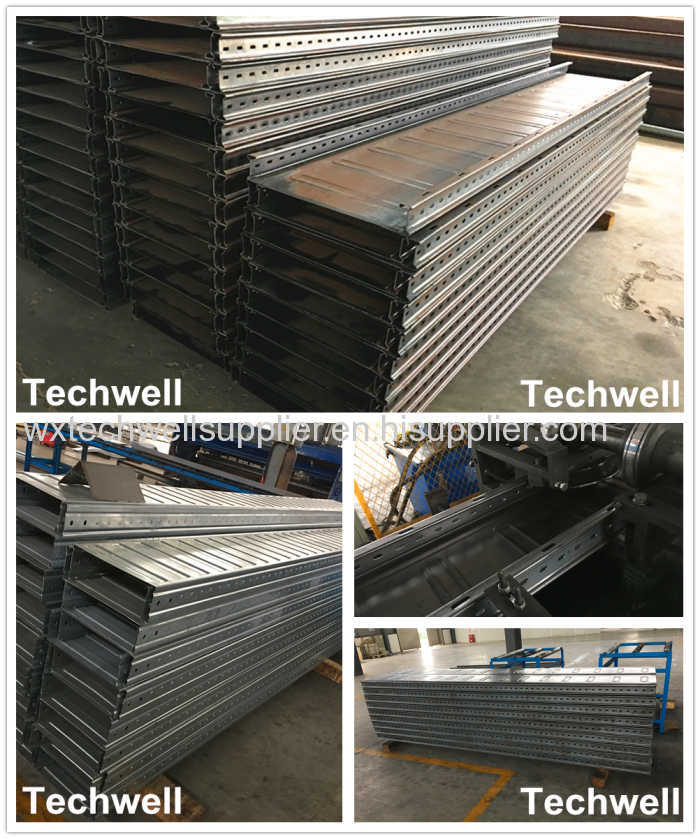

CT600 Ladder Type Perforated Cable Tray Roll Forming Machine, Cable Tray Production Line

Auto Size Changing Cable Tray Profile Making Machine / Cable Tray Manufacturing Machine

Cable Tray Profile Drawing & Finished Sample Sheets

Main Specifications

1). 7 Ton Hydraulic Uncoiler

Machine frame: welding structure with shot lastingtreatment

Description: Put the coil to the mandrel, the hydraulic cylinder will tighten the coil.

Start the machine, the motor will drive the mandrel at first, then the steel sheet will be released to the leveling

Electric releasing coil, hydraulic expanding, tension

Weight capacity: 7 Ton

I.D: 508mm

Motor Power: 5.5KW

Hydraulic System Power: 4KW

2). 7 Roller Leveling Machine

2 Rollers pinch feeding, 7 rollers leveling

leveling roller diameter: about Φ 90mm

Leveling roller material: high grade 40Cr

Heat treatment of leveling roller: surface Hi-frequency quench treatment

Leveling motor power: 4KW

3). Servo Feeding Machine

Servo motor power: 3KW

Servo motor brand: YASKAWA (JAPAN)

To exact accurately feed the sheet into punching machine according to the set program

4). Hydraulic Pre-Punching Machine

Punching Die: Cr12 Mov, quenching process

Punching Die size: according to drawing

Punching Power: 15KW

Punching controlled by PLC

5). Main Cable Tray Roll Forming Machine

Forming material thickness: 1.5-2.5mm

Forming material type: GI or Carbon Steel

Machine Frame: high grade steel welded and tempering treatment

Shaft Material: 40Cr high grade Steel tempering treatment (HB220-260)

Shaft Diameter: Φ 65mm

Bearing: HRB bearing ( Top Chinese brand )

Roller Material: high grade GCr15 steel, and roller surface with hard chrome ≥ 0.05mm

Forming Station: ≈ 18 stations

Forming Speed: 0-15m/min excluding punching / cutting time

Forming Motor: ≈15KW

Width adjustable motor ≈1.5KW

Size adjustment: electrical power adjustment

Drive type: Chain Drive

6). Hydraulic Cutting & Hydraulic Station

Cutting type: Hydraulic Post-cutting after roll forming,

When Cutting, Machine stop

Cutting blade material: Cr12Mov, Quench treatment, HRC58-62

Hydraulic Station Power: 15KW

7). PLC Control System

The entire line is controlled by imported PLC, LCD touch screen human-machine interface. People interact with the PLC. Operator by setting the program to run automatically (programmable control) to monitor and control process, to achieve the operator to control the production line and modify the control parameters, and real-time monitoring of equipment status, operating parameters and fault indication. Work piece length digital setting, work piece length adjustable. Real-time monitoring of equipment operating status and fault indication.

Operation: manual / automatic. It is convenient to maintenance with the manual model and there are emergency stop bottom on it.